Turkey’s Chromium Mining is on the Threshold of Mandatory Structural Conversion

Playing a leading role in world chromium mining since 1860, Turkey’s share in global chromium market has moved down to the fourth place due to technical and socio-economical processes in and out of the country and introduction of South Africa, Kazakhstan and India chromium in recent years. Turkey’s chromium ore production quantity is also on decrease. Production in year 2011 exceeded 2,5 million tons whereas it gradually decreased in the following years down to 1,5 million tons in year 2015, which is 5% ıf global chromium production. Sellable chromium ore production in year 2016 is expected to occur below 1 million tons.

On the other hand, well-established entities of Turkey’s chromium mining, Eti Krom, Eti Elektromet and Türk Maadin relatively remained out of these detrimental developments thanks to their modernization and improvement works as well as vertical integration in and out of country.

Turkey is also importer of chromium at cast sand and chemistry quality. Although ferro-chromium production is available in Turkey, ferro-chromium is imported. Turkey being unable to establish chromium/ferro-chromium/stainless steel chain nor could achieve sufficient chromium alloy steel production is to partially import stainless steel as well as qualified and tool steels.

In consideration of the above, the areas in which Turkey’s chromium mining has been unable to cope with was questioned, and the answer is innovation, cooperation, consolidation, integration concepts.

In this article, outlook of globe’s chromium/ferro-chromium/stainless steel sector in year 2015 as well as global position of Turkey’s chromium deposits in terms of competitiveness are addressed, and upcoming need for mandatory structural conversion is analyzed.

Outlook of Chromium Use Around the Globe

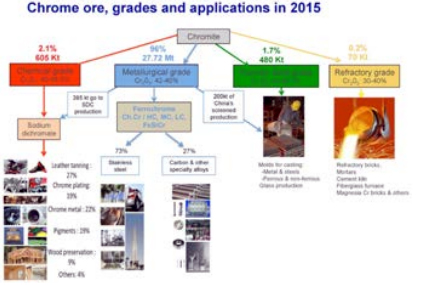

Out of 28,9 million tones chromium ore consumed in year 2015, 27,7 million tons were used in ferro-chromium production, 605 thousand tones were used to obtain chromium chemicals and metal chrome, 480 thousand tones were used in cast sand industry, and 70 thousand tons were used in refractor brick-mortar production. 20,2 million tons of produced ferro-chrmium were used in stainless steel, and 7,5 million tons were used in special alloy steels (qualified and tool steels).

Global Chromium Production, Trade and Prices

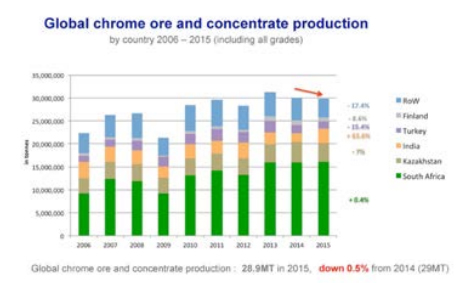

Global chromium piece and concentrate production in year 2015 occurred as 28,9 million tones with a 0,5% recession compared to previous year. Production in South Africa was 16,1 million tons with 54% share, Kazakhstan was 4,2 million tons with 14% share, India was 3,2 million tons with 11% share, Turkey was 1,5 million tons with 5% share, Finland was 0,9 million tons wit 3% share. Other large producers are Albania (0,7 million tons), Iran (0,5 million tons), Oman (0,5 million tons) and Pakistan (0,3 million tons).

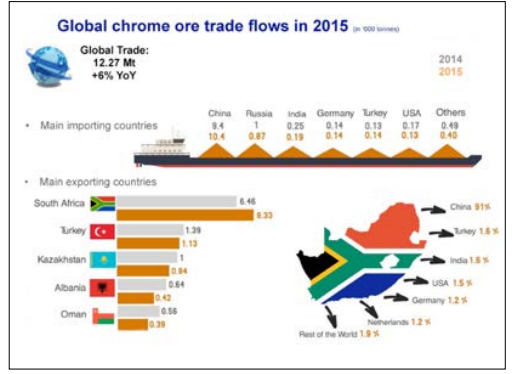

Chromium ore trade reached to 12,3 million tons in 2015. Primary exporter countries are South Africa with 8,3 million tons, Turkey with 1,1 million tons, Kazakhstan with 0,8 million tons, Albania with 0,6 million tons and Oman with 0,4 million tons. Primary importer countries in 2015 were China with 10,4 million tons equal to 91% share, Russia with 0,9 million tons equal to 7% share. Other important importer countries are Sweden (281 thousand tons), India (193 thousand tons), Germany (139 thousand tons), Turkey (136 thousand tons), USA (130 thousand tons), Holland (97 thousand tons) and Japan (53 thousand tons).

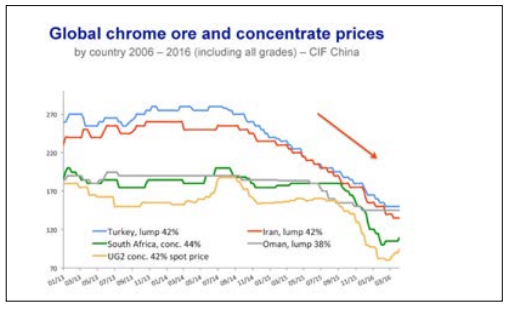

The chart indicates fluctuations in chromium ore prices by their origin at main ports of China per years (2013-2016), which has 91% share in chromium ore trade. Prices hit the bottom in 2016 February began to rise in March and reached to levels close to year 2015. China delivery price of 46-48% Turkish concentrate as of July 2016 is 220-225 usd /dmt, price of 40-42% piece ore is 210-215 usd /dmt.

2015 Outlook of Global Ferro-Chromium Production and Trade

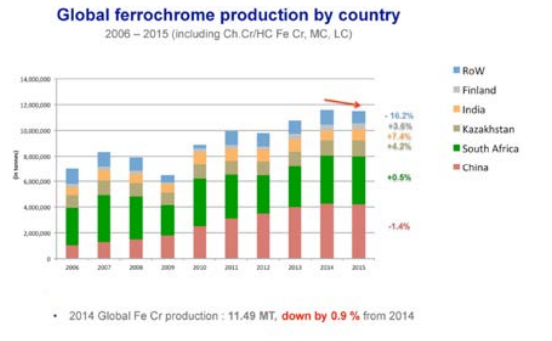

- Global High Carbon Ferro-Chromium (HC FeCr) production in year 2015 occurred as 10,7 million tons with 1% decrease compared to year 2014. Out of this production, China has a share of 3,8 million tons, South Africa has a share of 3,8 million tons, Kazakhstan has a share of 1,2 million tons, India has a share of 0,9 million tons, Finland has a share of 457 thousand tons, Brazil has a share of 137 thousand tons, Russia has a share of 116 thousand tons, Zimbabwe has a share of 107 thousand tons, Turkey has a share of 94 thousand tons, Sweden has a share of 84 thousand tons, Oman has a share of 72 thousand tons, Albania has a share of 43 thousand tons.

- Out of China’s 10,4 million tons of chromium ore consumption in year 2015 by ferro-chromium industry; South Africa’s share increased to 73% with 7,6 million tones. Turkey’s share was 10 %, Albania’s share was 5%, Iran’s share was 4%, Pakistan and Oman’s shares were 3% each.

- Major 20 large companies around the globe producing HC FeCr are; Glencore-Merafe (S. Africa) 1,6 million tons, Samancor (S. Africa) 1,1 million tons, Kazchrome – ENRC (Kazakhstan) 1,1 million tons, Sinosteel (ASA, Tubatse, Zimasco, Jilin) 1,1 million tons, Outokumpu (Finland) 530 thousand tons, Etikrom –Vargöen – Tikhvin Group 520 thousand tons, Hernic (S. Africa) 450 thousand tons, Sichuan Ehui (China) 350 thousand tons, Xianganglian (China) 350 thousand tons, Mintal, Taigang Wanbang, Tianyi, IMFA, IFML, Ferbasa, Hengshan, Tata, Jindal, Facor and RFTL.

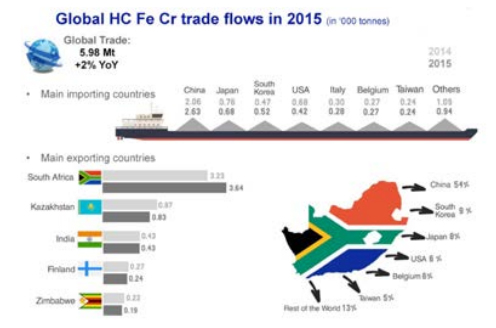

Total global high carbon ferro-chromium (HC FeCr) trade in year 2015 was 6,0 million tons. China has a share of 54% with 2,6 million tons, Japan has a share of 11% with 676 thousand tons, South Korea has a share of 9% with 522 thousand tons, USA has 420 thousand tons, Italy has a 285 thousand tons, Belgium has 273 thousand tons, Taiwan has 244 thousand tons (China), Germany has 173 thousand tons, Spain has 172 thousand tons, France has 100 thousand tons in the import. Turkey’s HC FeCr import in year 2015 was 6,6 thousand tons.

Primary exporter countries are South Africa with 3,6 million tons, Kazakhstan with 830 thousand tons, India with 430 thousand tons, Finland with 240 thousand tons, Zimbabwe with 190 thousand tons, Turkey with 82 thousand tons and Russia with 72 thousand tons. Turkey is both importer and exporter of ferro-chromium.

Year 2015 Global Low Carbon Ferro-Chromium Production and Trade

Low carbon ferro-chromium (LC FeCr) production in 2015 occurred as 767 thousand tons, and main producers are China with 52% share equals to 397 thousand tons, Russia with 27% share equals to 208 thousand tons and Kazakhstan with 8% share equals to 58 thousand tons. In year 2015, South Africa produced 26 thousand tons, Japan produced 23 thousand tons, Germany produced 20 thousand tons, Turkey produced 17 thousand tons. Total global trade in year 2015 was 350 thousand tons. Main importer countries are Japan with 54 thousand tons, USA with 54 thousand tons, Germany with 33 thousand tons, South Korea with 33 thousand tons. Turkey’s LC FeCr import in 2015 was 3,9 thousand tons. Other significant countries having import amounts exceeding 10 thousand tons are Italy, Holland, Spain, France and India. Major exporter companies are China, Russia, Kazakhstan, South Africa and Germany. Turkey’s LC FeCr export for the same year was 10,6 thousand tons.

Global Chromium / Ferro-Chromium Sector Foreign Trade Balance

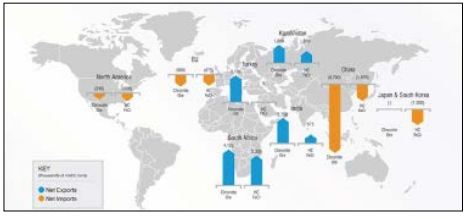

Outlook of global chromium ore – ferrochromium import and export structure in year 2010: South Africa, Kazakhstan, India and Turkey were clearly exporter companies whereas Northern America, European Union, China, Japan and South Korea were clearly importers.

In 2015, although India’s chromium ore export significantly reduced, it is retaining same existence outlook.

Global Use of Chromite as Cast Sand in 2015

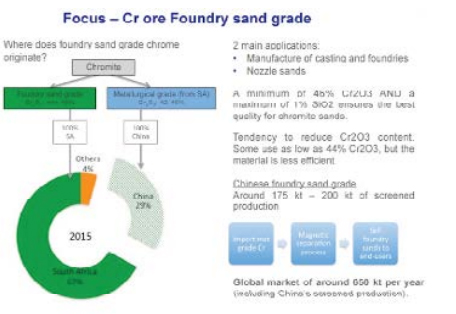

“Chromite” with refractor property is used as cast sand in ferrous and non-ferrous cast industry as well as for making cast parts required in automotive, ship construction and heavy industrial facilities. Metallurgical chromium ores pass through magnetic separators to reduce SiO2 percentage below 1% for that purpose. Two major chromite cast sand manufacturers in the world are South Africa and China.

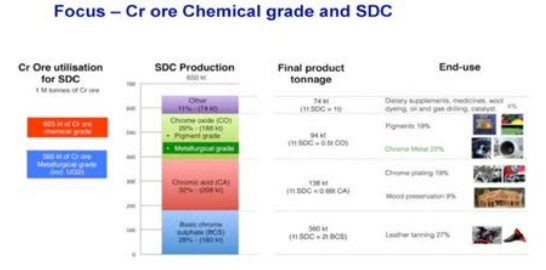

Year 2015 Global Chromite Use in Chromium Chemicals Sector

In 2015, only 3% of the world’s chromium production is used in chromium chemicals. Sodium chromate is the main product of chrome chemicals, followed by sodium bichromate, sodium, ammonium and potassium dichromate, chromic acid and basic chromium sulfates among others. Chromium compounds are used in paint, metal coating and wood protection industries, leather tanning and to obtain metal chrome. Metal chrome is required in super alloys for resistance against excessive temperatures and corrosion (such as jet engines). A Turkiye Sise Cam Group company Mersin Soda Sanayii A.Ş. is among the important chromium chemicals manufacturers.

Global Stainless Steel (SS) Sector Outlook in 2015

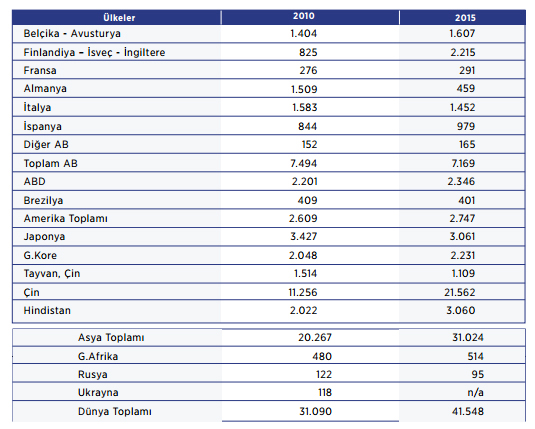

Stainless Steel Production of Countries by Years (x thousand tons)(ISSF)

Global SS production which was 1 million tons in year 1950 has reached to 6,9 million tons in 1980, 31,1 million tons in 2010, and 41,6 million tons in 2015.

Share of SS production in the same year out of 1.623 thousand tons raw steel was only 2,5%.

SS production and consumption between years 2005 – 2015 grew by two digit rates each year (10-12%), but growth rate for year 2016 and onwards is expected to be 5,5% - 6by slowing growth in China.

14 out of 20 large scale SS manufacturers around the world are established in China. They (Tisco, Tsingshan, Baosteel, Posco, NSSMS, Lisco, Waishin Lihwa, Chengde, Jisco, Jinguang, Nisshin, Yusco, Wahang ve Xinjinhua) procure their ferrochromium need from over 150 small to large scale entities established in China (6,3 MVA - 40MVA), over 300 local companies having electrical arc furnace as well as import. Ferrochromium prices announced by Chinese SS manufacturers or identified by tenders directly impact ore prices of Turkish chromium manufacturers just like exporters in other countries. The largest SS manufacturers other than China are Outokumpu, Acerinox, Aperam and Jindal.

Today, more than 50% of SS production and consumption occurs in China, and this rate gradually increase every year.

General Characteristics of Known Chromium Deposits in Turkey and Around the World

Mineralogy

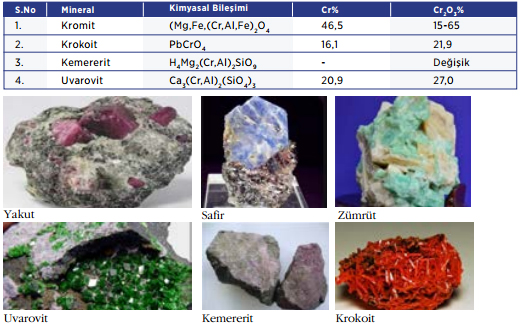

Although chromite mineral was discovered by Russian geologist in 1765, it was named by French chemist Vanquelin. Vanquelin discovered presence of chromium element different color property of chromium compounds while he was working on crocoite mineral (P6 CrO4 ) brought from Siberia in 1797, and named the element as Chromite derived from “khroma: color” in Greek. Precious gems like emerald, ruby and sapphire get their green, red, blue, yellow colors from more or less iron and vanadium as well as chromium. Kemererite (available in Turkey only) and uvarovite minerals formed by metamorphism of chromium deposits are popular among collectors.

Some of the Chromium Minerals

Chromite

Chromium ore is generally formed during the process of melt magma rising and hardening, and available within ultramaphic rocks constituted of minerals rich in iron such as olivine and pyroxene. Spinel minerals are a complex mineral group, mainly constituted of MgO and Al2 O3 components. Chromium spinel (chromite) [(Fe, Mg)O. (Cr, Fe, Al)2 O3 ] mineral is the only chromium mineral that has an economic value, it contains varying amounts of chromium and iron depending on deposit formation mechanism. In the chromite mineral, magnesium is replaced with varying amounts of bivalent iron, rarely with nickel, manganese and zinc whereas aluminum is replaced with varying amounts of trivalentd chromium and iron. Whilst this affects Cr2 O3 grade of the ore, it particularly defines Cr/Fr ratio which identifies chromium content of produced ferrochromium as well as reduction facility index of the ore during metallurgical processes.

Generally, refractor (reduction resistance) index formula for the ore is as follows.

FThe bigger refractor index of chromium, harder it is to reduce the ore at ferrochromium furnaces. If the ratio of bivalent magnesium to bivalent iron increases, reduction of the ore becomes difficult. However, if the ratio of trivalent iron to trivalent aluminum increases, reduction of the ore becomes easier. The less amount of powder is present in piece ore directly charged into furnaces (-10 mm) the more smelting yield will be. MgO /Al2 O3 ratio is another factor affecting smelting yield, a ratio over 2,0 will enable ease of sales and premium.

Olivine

(Mg+2, Fe+2)2 SiO4 is mostly constituted of 70% Forsterite (Mg2 SiO4 ) and 30% Fayalite (Fe2 SiO4 ). It gets the olive green color from nickel, oxidizes due to decomposition and turns red.

Semi-precious gems peridote and chrysolite crystals are named after olivine. Olivine samples extracted from Chrysolite island in Red Sea are called Zebercet stone in Turkey.

It is the first mineral that left aqueous environment after hardening of ultrabasic magma. It is resistant against heating and cooling, therefore used as sauna stone. It also functions as melting pot plug before casting inside high furnaces in iron steel industry.

Forsterite melts at 1900 o C under atmospheric pressure, therefore it is particularly preferred in aluminum cast sand industry.

Olivine used in metallurgy industry is preferred to have MgO amount over 46%, total FeO amount less than 8%, and SiO2 amount in the range of 38-42%.

Pyroxene

General formula is XY (Si, Al) 2O6, X compound is mostly constituted of bivalent iron, calcium, sodium and magnesium, whereas Y compound is mostly constituted of little chromium, aluminum, trivalent iron and magnesium. Y compound may contain cobalt, manganese, scandium, titanium and vanadium elements. Pyroxenes containing low Ca and high Mg are named as “orthopyroxene”, and pyroxenes containing high Ca, low Mg are named as “clinopyroxene”.

Together with olivine, it is one of the two main minerals earth’s upper mantle. It has black or dark green color. It is glossy like glass. Nephrite and jade are formed by metamorphism of pyroxene. Objects made of these precious gems are of high value in China and Far East. Precious gems such as sapphire, ruby and zoisite are also observed (Malatya – Doğanşehir) in meta-pyroxenes .

Geological Environment Where Chromite is Formed and Alterations

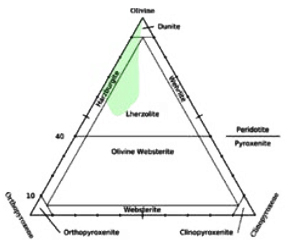

Chromium deposits are only found in ultramaphic depth rocks and their decomposition products. Ultramaphic depth rocks are magmatic or meta-magmatic rocks that contain SiO2 less than 45%, high FeO and MgO.

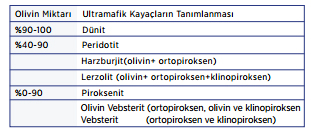

They form the earth’s mantle and classified mainly under three groups of dunite, peridotite and pyroxenite. They have different names depending on type and rates of olivine and pyroxene minerals.

Ultramaphics are observed in stable continent regions in regular layers, and in two diverse environments as tectonites and cumulates within ophiolitic piles. Tectonites are the rocks deformed under metamorphism or tectonite shear or tensile forces, and their mineral containment demonstrate directional texture. Cumulates are formed at the end of floating or sinking processes of crystals derived from magma and settled in layers within geosynclinals which are formed within stable continent regions or in between continental arches.

Maphic rocks such as Gabbros (diabase, dolerite and micro-gabbro) (formed of plagioclase and clinopyroxene) and Norite (formed of plagioclase and orthopyroxene) are found in layers over cumulate zone of ultramaphic pile or as dikes inside tectonite zone.

Triangle diagram of Olivine, Orthpyroxene, Clinopyroxene minerals that form-name rocks

(In addition to these constituents, plagioclase, spinel or garnet may be present in dunites and peridotites. They are transformed to serpentinites due to decomposition of olivine and pyroxenes. Dunites and Peridotites are the most important and common groups of ultramaphites. They have a dark green color; however, they turn light greenish, blackish green or nearly black color as a result of serpentinization. They are mostly important chormite bearing rocks. Lateritic iron, cobalt and nickel deposits are formed due to decomposition in tropical climates, and form listvenitic gold deposits due to decomposition by liquids rich in CO2.)

(Pyroxenites are relatively common in ultramaphic rocks and they are resistant against alteration. Contained minerals are generally constituted of monoclinic and orthorhombic pyroxene. Rocks may also contain trace amounts of iron oxide minerals, olivine, plagioclase and spinel.)

Serpentines (Mg3 Si2 O5 (OH)4 )